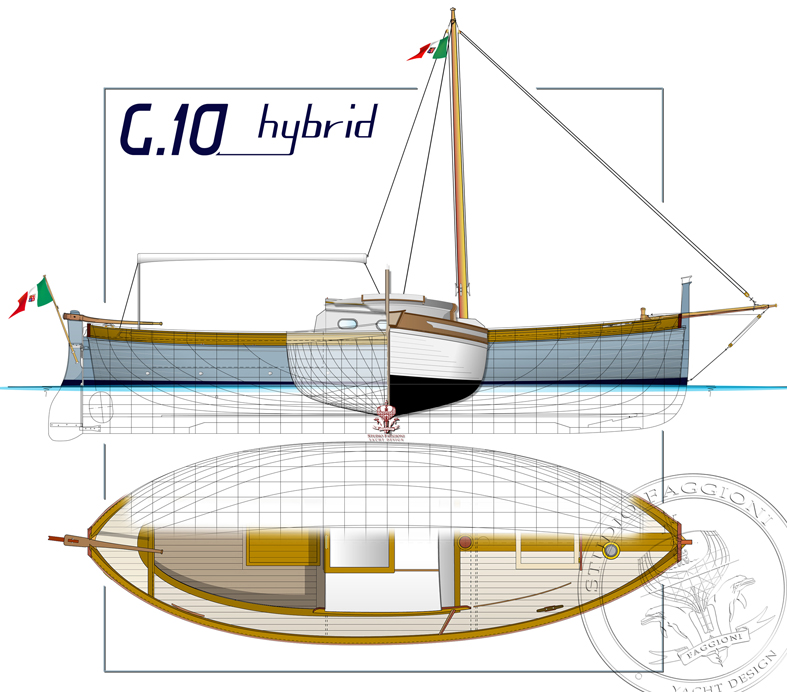

Gozzo G10

| Shipyard: | ACL Aprea |

| Year of Project: | 2019 |

| Yacht Type: | full Project |

| Hull Length: | 10 |

| Hull Width: | 3.3 |

| Work Type | full Project |

| Publications | |

| Link: | https://www.youtube.com/watch?v=XXKZwJ-6HMs |

The concept of this project originated in the idea of offering a traditional wooden boat to a public that in the past had had to give up this dream because of the big difference in production and maintenance costs between a boat made in traditional caulked planking than one in fibreglass. "Nino had been thinking of investing in a project like this for years," says Faggioni, "and in 2010 we created what we called the 'slow coast' project. We wanted to mass-produce a kind of traditional boat that was ecological and proudly slow as it sailed along the coast, completely against the trend of how people still today sail the sea. Obviously the time was not then ripe, also because slow coast aimed to be a philosophy, a kind of movement, designed not just to build new boats."

Today, Antico Cantiere del Legno of Giovanni Aprea (ACL Aprea) has expanded in the Torre Annunziata area and conditions favourable to the project have been created. The use of build technologies using numerically controlled machines, laminated wood and layered wood has made it possible to imagine the mass production of traditional wooden Sorrentine gozzos with accelerated production times (a big reduction of production times above all in building frames that arrive with components already cut and ready to assemble) and reduced costs.

If this concept will win the challenge ? this is what designer and yard are betting on especially for the Campania market "which still has a lot of seagoing culture" ? and if the time really is ripe, only the market will decide. It is not possible fully to evaluate on paper the impact on possible owners of boats of this kind, but the launch of this first prototype, scheduled for August 2018, is now close?

The ambition: to give mass production a soul

Components are obviously assembled and finished by hand: mass production thus becomes part of high craftsmanship.

Already in carrying out the restoration of La Spina, Faggioni, who knew that many wooden parts of the boat would be machine made, used manual finishing with the characteristic tiny imperfections it involves. Knowingly, these tiny imperfections, normal signs of craftsmanship, "warmed" the effect of the finished product giving an added value that went beyond the perfection of cold machines. In the case of Gozzo 10 everything was done as in perfectly normal mass production with the sole difference that the final presence of craftsmen is more evident than in other production runs. It is a spontaneous variable, not designed but foreseen, that makes every boat unique. "Our ambition was to give a soul to mass production which here loses its impersonal aspect," says Faggioni. This mass/craft approach is certainly not radical with respect to tradition. However it is possible that this build method makes it possible for tradition to survive and find new energy, preserving it from the risks of extinction.

Says Faggioni: "I honestly believe that this kind of build, that fully uses the tradition of master carpenters but with a nod to new technology, could be carried out only by Giovanni ?Nino? Aprea whose yard has never given up using wood. In these years Nino has amply demonstrated he knows how to bear an important name in the world of wooden boats, combining tradition and innovation.

Then I like to believe that there has been the influence of our constant collaboration and search for an alternative way to work on boats, a new application of Arts and Crafts à la William Morris?.

Build technologies

The boat has a transverse structure. The keel was assembled with pieces of solid iroko and preparing it demanded a lot of care from the craftsman, who are experts, because every later piece of the frame would have to be placed with precision in the points indicated by the 3-D design to avoid distorting the planking. The stern post and stem post were sculptured using a milling machine from raw blocks of laminated wood.

The 26 ribs that make up the side frames are placed at constant intervals and rest on the keel. They are tied together by the centre keelson in Iroko, three battens and an external stringer in Iroko. Each rib is a closed structural ring and is made up (to limit the waste in cutting the panels) of four elements: a floor, two frames and a beam. This closed ring, unlike in the traditional methods, makes it possible to have elements that no longer sit side-by-side but lie on the same plane. A structure made in this way has a very favourable strength/weight ratio and is also aesthetically clean looking. Every part, as mentioned, was cut with a five axis numerically controlled milling machine that guarantees precision to one 10th of a millimetre. The high precision of the cuts made it possible to design each surface of the edges of the various components with correct ?quartabono? angles and joints of absolute precision. Dovetail joints were designed to reduce to a minimum the risk of imprecision or human error during assembly: all components are joined together using epoxy glue, pins and screws in stainless steel.

As a result, in the yard the assembly of the components ? every single piece is unambiguously marked with a number during milling ? can be done quickly, without uncertainty, corrections or chocking and guarantees that the result will be as laid down in the design.

The now finished hull, the number one, has a double layer of mahogany planking laid out longitudinally and overlapping, glued with epoxy resin. This provides a very strong shell that will be leakproof. For the planks of the garboard and the sheer there are bulges in the thickness only for "linguistic" reasons and to respect tradition.

However, later hulls will be modified and will be made by the yard with planking overlapping at an angle of 45°. Obviously, this kind of planking needs no caulking with obvious advantages for maintenance costs.

text by Giacomo Gori

«« Back to Yacht List ««